Accrediting agencies look for traceability processes that are compliant with evidence-based standards and guidelines. The trophon2 device with AcuTrace® RFID technology simplifies the creation of accurate digital records, easily obtained from your trophon2 device to support audit-readiness.

Accrediting agencies look for traceability processes that are compliant with evidence-based standards and guidelines. The trophon2 device with AcuTrace® RFID technology simplifies the creation of accurate digital records, easily obtained from your trophon2 device to support audit-readiness.

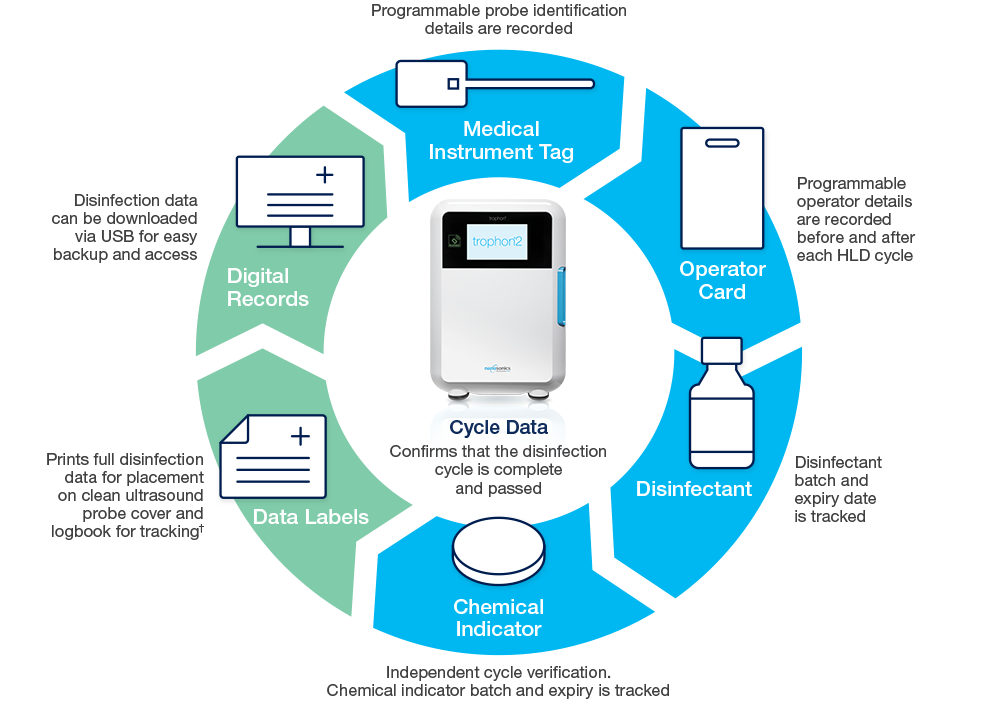

Automated Digital Traceability Across the Workflow

The trophon2 device increases user compliance and supports audit-readiness through automation, capturing data across the entire reprocessing workflow.

AcuTrace RFID technology records operator, probe and cycle data to capture and demonstrate user compliance.

AcuTrace-enabled consumables and accessories include:

Audit-Ready Compliance and Archiving

AcuTrace technology simplifies the creation of accurate digital records, accessible on your trophon2 device to support audit-readiness. AcuTrace technology electronically captures disinfection data in accordance with requirements in USA, CAN, ANZ, UK & EU.1-14

This data is easily accessible to suit a variety of user traceability methods:

- Printer label capturing AcuTrace inputs and disinfection results

- Download disinfection records to USB

- Optional AcuTrace® PLUS allowing API access, supporting digital disinfection data archiving*.

*Custom API middleware required to enable this capability. All connectivity, configuration and integration with customer IT systems is the responsibility of the customer.

The trophon® family includes trophon® EPR and trophon®2 which share the same core technology of 'sonically activated' hydrogen peroxide.

- AORN 2018. High-Level Disinfection. In: AORN Guidelines for periOperative Practice. Denver, CO.

- ANSI/AAMI ST58:2013 Chemical sterilization and high-level disinfection in health care facilities.

- CDC 2008 Guideline for Disinfection and Sterilization in Healthcare Facilities.

- AS/NZS 4815:2006 Office-based health care facilities - Reprocessing of reusable medical and surgical instruments and equipment, and maintenance of the associated environment.

- AS/NZS 4187:2014 Cleaning, disinfecting and sterilizing reusable medical and surgical instruments and equipment, and maintenance of associated environments in health care facilities.

- ACIPC/ASUM 2017. Guidelines for Reprocessing Ultrasound Transducers. Australasian Journal of Ultrasound in Medicine. 2017;20(1):30-40.

- Australian Commission on Safety and Quality in Health Care. National Safety and Quality Health Service Standards, second edition. November 2017.

- CAN/CSA-Z314-18. Canadian Medical Device Reprocessing. February 2018.

- Health Service Executive. Quality Improvement Division (2017). HSE Guidance for Decontamination of Semi‐critical Ultrasound Probes; Semi‐invasive and Non‐invasive Ultrasound Probes.

- Health Protection Scotland (2016). NHSScotland Guidance for Decontamination of Semi-Critical Ultrasound Probes; Semi-invasive and Non-invasive Ultrasound Probes.

- Welsh Health Technical Memorandum (2014). WHTM 01-06 - Decontamination of flexible endoscopes Part C: Operational management,

- Department of Health (UK) (2016). Health Technical Memorandum 01-06 Part C Operational management.

- Ministère des affaires sociales et de la santé (2016). INSTRUCTION N° DGOS/PF2/DGS/VSS1/2016/220 du 4 juillet 2016 relative à relative au traitement des endoscopes souples thermosensibles à canaux au sein des lieux de soins.

- Kommission für Krankenhaushygiene und Infektionsprävention and Bundesinstitut für Arzneimittel und Medizinprodukte. Anforderungen an die Hygiene bei der Aufbereitung von Medizinprodukten